Table of Contents

Hanoi, Vietnam – January 16, 2026

Vietnam has reached a historic milestone in its semiconductor journey as Viettel officially broke ground on the country’s first semiconductor fabrication plant at the Hoa Lac Hi-Tech Park in Hanoi.

The project marks the first time Vietnam establishes domestic chip manufacturing capabilities, completing a critical missing link in the global semiconductor value chain and signaling the country’s transition from assembly and testing toward higher-value manufacturing.

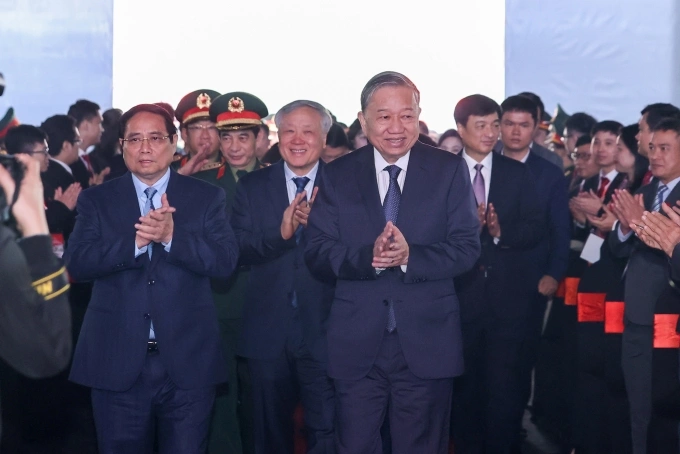

The groundbreaking ceremony was attended by Vietnam’s top leadership, underscoring the strategic importance of semiconductor technology to national economic development, digital transformation, and technological sovereignty.

Completing the Semiconductor Value Chain in Vietnam

A complete semiconductor product typically goes through six major stages:

-

Product definition

-

System design

-

Detailed IC design

-

Chip fabrication

-

Packaging and testing

-

System integration and validation

Until now, Vietnam has participated in five of these stages, with chip fabrication remaining the most complex and capital-intensive gap. The launch of this fabrication facility represents a decisive step toward closing that gap and establishing a fully integrated semiconductor ecosystem within the country.

Located on a 27-hectare site, the facility is designed as a national infrastructure platform supporting research, design, prototyping, manufacturing, and testing of semiconductor devices. When operational, it is expected to serve critical sectors including telecommunications, aerospace, automotive, medical devices, industrial automation, and Internet of Things (IoT) applications.

A Strategic Investment in Advanced Manufacturing

Semiconductor fabrication is widely regarded as one of the most technologically demanding manufacturing processes in the world. From ultra-pure silicon wafers, chips are created through approximately 1,000 tightly controlled process steps over several months. Even minor deviations can compromise yield and reliability, requiring exceptional precision, operational discipline, and engineering expertise.

The project is planned for phased implementation between 2026 and 2030, starting with facility construction and technology transfer, followed by pilot production and gradual optimization of manufacturing processes. Long-term planning allows for future expansion and advancement toward more sophisticated semiconductor technologies.

Vietnam’s Growing Role in the Global Semiconductor Landscape

The establishment of a domestic fabrication facility reflects Vietnam’s broader ambition to move deeper into the global semiconductor supply chain. Over recent years, the country has emerged as a key destination for semiconductor assembly, packaging, and testing, while also building capabilities in IC design and engineering services.

Vietnam currently hosts a rapidly expanding semiconductor workforce, with thousands of engineers actively engaged across design, testing, and manufacturing-related activities. Major global semiconductor players have increased investments and partnerships in the country, reinforcing Vietnam’s position as a strategically important hub amid ongoing supply chain diversification.

A New Chapter for the Vietnamese Semiconductor Ecosystem

The launch of Vietnam’s first semiconductor fabrication plant represents more than a single investment project—it signals a structural shift in the nation’s industrial capabilities. By combining policy support, long-term infrastructure development, and a growing talent base, Vietnam is positioning itself as a credible participant in advanced semiconductor manufacturing.

As the global industry continues to seek resilient, diversified, and technologically capable supply chains, Vietnam’s semiconductor ecosystem is entering a new phase—one defined by deeper integration, higher value creation, and long-term sustainability.

Tiếng Việt

Tiếng Việt